CNC Turning jinis stainless steel / aluminium kopling fleksibel kanggo motor

Kopling Rahang Mlengkung

Kopling Jaw Mlengkung bisa digunakake ing pirang-pirang aplikasi lan dadi kopling kabeh-tujuan.Desain dhasar saka Jaw Mlengkung ngidini kanggo kapasitas torsi sing luwih dhuwur ing desain kompak.Waos sing mlengkung nduweni area kontak sing luwih gedhe sing menehi kapasitas torsi dhuwur, lan nyuda tekanan pinggir.Bakal nampung misalignments poros sumbu, radial lan sudut.

Hub digawe saka macem-macem bahan kalebu: aluminium, abu-abu, wesi, baja, baja sinter, lan stainless steel.Unsur laba-laba kasedhiya ing macem-macem opsi durometer ing Urethane & Hytrel.Laba-laba bisa nindakake ing kahanan siklus tugas normal nganti siklus tugas abot sing kalebu beban kejut lan bisa nyuda getaran torsi ing sistem.

| Model | Ukuran bor (mm) | Torsi Rated (Nm) | Torsi Maks (Nm) | kacepetan maksimum | Diameter njaba (mm) | Dawane (mm) | Toleransi Bore (mm) |

| HS -TCN-14C | 3~7 | 0.7 | 1.4 | 45000 | 14 | 22 | +0.6~0 |

| HS-TCN-20C-R | 4~11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0.8~0 |

| HS-TCN-30C-R | 6~16 | 4 | 8 | 21000 | 30 | 35 | +1.0~0 |

| HS-TCN-40C-R | 8~28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1.2~0 |

| HS-TCN-55C-R | 9.5~32 | 17 | 34 | 11000 | 55 | 78 | +1.4~0 |

| HS-TCN-65C-R | 12.7~38.1 | 46 | 92 | 9000 | 65 | 90 | +1.5~0 |

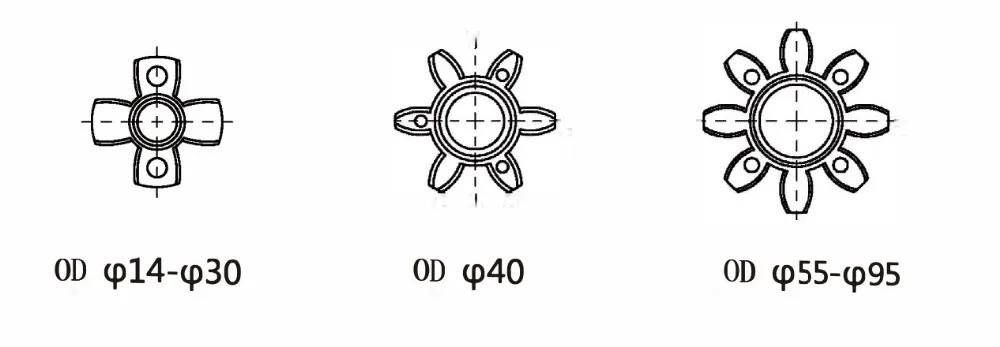

Karakteristik Spider

Kopling rahang mlengkung kalebu loro hub logam lan unsur "laba-laba" elastomer.Laba-laba kasedhiya ing

durometers atose beda, saben gampang dikenali dening werna.

| Kekerasan | warna | Bahan | Range Suhu | Aplikasi |

| 80 Pesisir A | Biru | Polyurethane | -50 ~+80 .C | Dampingan sing apik banget |

| 92 Pesisir A | kuning | Polyurethane | -40~+90.C | Damping moderat, aplikasi umum |

| 98 Pesisir A | abang | Polyurethane | -30 ~+90 .C | Aplikasi torsi dhuwur |

| 64 Pesisir D | Ijo | Polyurethane | -50 ~+120 .C | Torsi sing luwih dhuwur, suhu dhuwur |

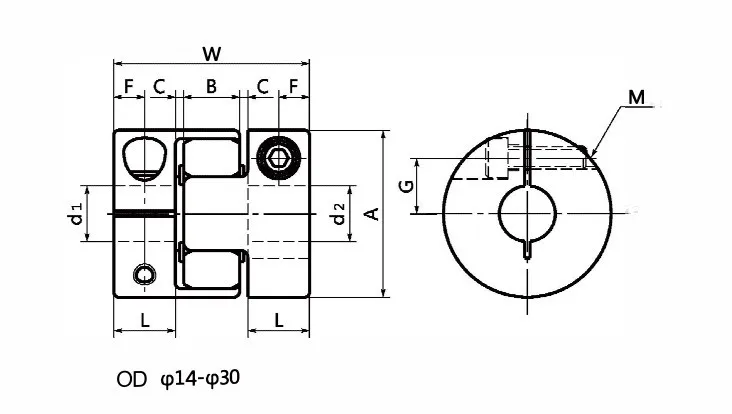

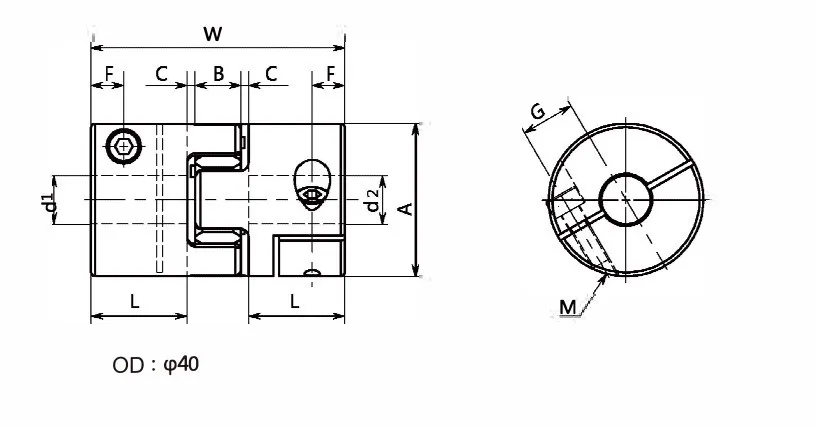

Informasi ukuran kopling

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6.5/7.5 | M2.5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |